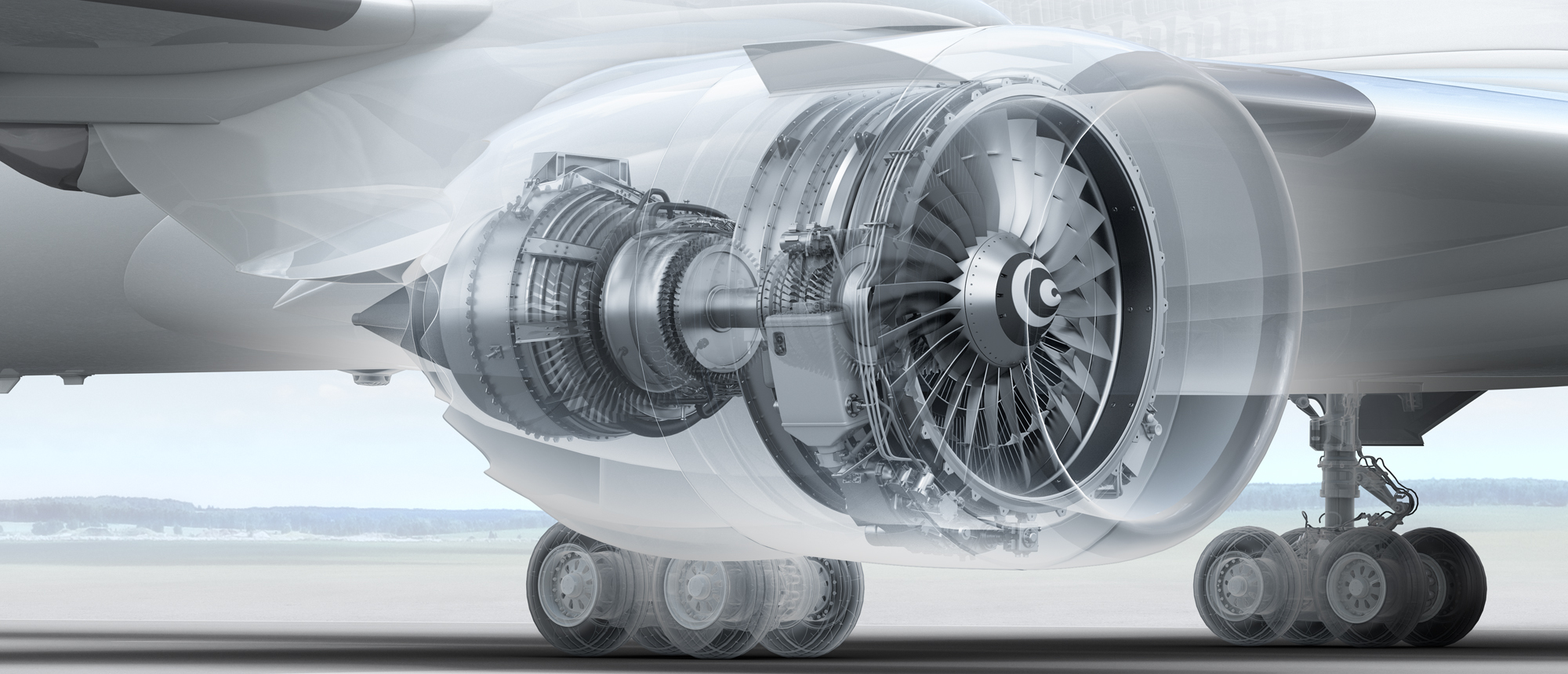

Aircraft Engine Controls

Woodward is the leading supplier of turbine engine control and combustion systems. As a single source for the entire system, our solutions help reduce development costs, minimize risk, streamline logistics and enhance integration

Fuel Control Systems

From aircraft fuel inlet to tightly controlled combustion, our fuel pumping and metering systems set the highest standards in pressurization and control with reliability and low fuel burn. Our servo valves and industry-leading technologies provide elegant, cost-effective solutions for high performance and reliability in harsh environments.

Features & Benefits Highlights

- Minimize program risks and increase reliability with our industry-leading performance and technological leadership based on millions of flight hours

- Dedicated analysis team facilitates system level tradeoffs between critical mission requirements, such as pump heat rejection, metering accuracy, disturbance rejection, weight and cost

- On-site engineering support ensures a flawless Entry Into Service (EIS) for new or replacement applications

- Cost savings over the product lifecycle of any turbine-based system

- Scalable component platforms reduce risk, cut development costs and boost reliability

Fuel Injection and Ignition Systems

Our fuel injection and ignition solutions meet OEM emissions requirements, while enabling optimal engine operation and performance. A range of designs precisely place atomized fuel for efficient and complete combustion.

Our valve, fuel control and ignition technologies can be combined for combustion solutions that improve liftoff at higher altitudes and difficult windmilling conditions.

Our SmartFire Ignition System combines atomization with ignition to meet the most demanding customer requirements.

Features & Benefits Highlights

- Fuel nozzle designs range from high performance pressure atomizing and air-blast tips to multi-circuit direct injection designs

- High- and low-tension ignition systems with solid-state exciters, long-life Igniters and sealed ignition leads

- Extensive range of certified parts for aerospace industry applications produced to specifications through advanced additive manufacturing

- Fuel control and ignition technologies can be combined for optimal combustion solutions

Engine Actuation Systems

Our actuation solutions meet the highest aviation performance standards. We provide complete system design, analysis and testing across a wide range of turbine engine applications. A fully optimized and validated suite of hardware enables flawless entry into service (EIS) invariable geometry, thermal management, turbine clearance control, engine operability and compressor bleed applications.

Features & Benefits Highlights

- World-class suite of technologies, including fueldraulic actuators, electro-mechanical actuators, air valves, specialty valves, servo controls, and position sensors

- Systems-level performance and accuracy stacks that include sensor effects over life and signal demodulation errors

- Optimal architectures and actuator placement based on your specific requirements

- Standard designs minimize development costs

Air Management

We provide high-performing air valves and air- metering technologies across the turbine engine environment. Turbine engine actuation, position sensing and servo systems provide highly reliable and cost-effective solutions. Canted shaft designs leverage decades of experience for reliable operation in harsh environments, including extremely high temperatures (>1450°F) and severe exhaust contamination.

Features & Benefits Highlights

- Air management and engine-oil solutions based on decades of technological leadership

- Air-management systems that operate in extreme conditions, including extremely high temps (>1,450°F)

- Broad application expertise to meet difficult requirements

- Highly reliable and cost-effective solutions delivered within severely condensed program schedules

- A CFD led approach yields significant system level cost and weight savings without violating stringent envelope constraints

- Innovative flow body designs to meet Class IV “bubble tight” sealing per ANSI/FCI 70-2 over life in extreme environments (equates to 0.01% of rated flow)

- Leverage of industry leading actuation and servo valve innovations that significantly reduce LRU and System envelopes while simultaneously improving reliability

- Fuel-powered and electromechanical actuation, which provides double digit reliability improvements

Oil Management

We are a global leader in custom oil flow and temperature control devices for direct drive and geared engine architectures. We provide aircraft turbine system performance enhancements via custom flow modulation, which includes flight critical applications in oil modulation, controlled bearing cooling flow, thermal management, heat exchanger bypass and your specific valves.

Features & Benefits Highlights

- Leading fuel, oil, actuation, air, and combustion systems

- Innovative systems approach to integrate fight critical, customized functionality while minimizing piece parts

- Highly reliable and cost-effective solutions delivered within severely condensed program schedules

- High reliability and lower risk with technology based on millions of flight hours