With over 50 years of heritage in the aerospace industry, Woodward applies total system solutions to your needs. We are at the forefront of the industry in developing and delivering motion control and integrated propulsion systems. Our product and system platforms can be application-engineered for a wide variety of performance and configuration requirements.

Category Featured Product

8923-2588

Power Generation SECM70

ECM-5642A-070-070-1703 DEV

The SECM70 is part of the engine management system for mobile industrial (forklift) and stationary (genset) applications.

8273-1012

2301E

LSSC, 24VDC, Hazard Location

The 2301E Full Authority Speed Control sets the speed or load of a diesel engine, gas engine.

8237-2600

ProTech-GII

HV/LV, VR, VI, Enhanced

A panel mount, high voltage/low voltage, voted relays, voted inputs with math functions protection device for steam turbine protection

8237-2601

ProTech-GII

HV/HV, VR, VI, Enhanced

A panel mount, high voltage/high voltage, voted relay, voted inputs enhanced protection device for steam turbine protection

8237-2608

ProTechTPS

HV/LV, VR, VI, Math

A panel mount, high voltage/low voltage power input, voted relays/voted input with math function total protection system.

8237-2609

ProTechTPS

HV/HV, VR, VI, Math

A panel mount, high voltage/high voltage power input, voted relays/voted Input math function total protection system.

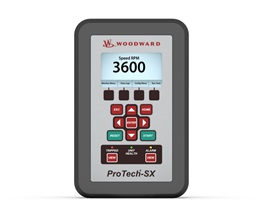

8237-1243

ProTech-SX

HV/HV

A panel mount, high voltage/high voltage power input, simplex safety device for steam turbine overspeed protection.

9907-1978

QuickTrip

2-out-of-3 Trip Block Assembly

An integrated 2-out-of-3 trip block assembly for safety systems to reliably trip low pressure oil headers for steam, gas, hydro systems.

8262-1141

5009XT

120V AC/DC, TMR, Configurable

The 5009XT is a highly reliable triple-redundant, fault-tolerant standard-off-the-shelf 120V AC/DC steam turbine control used in reliability-critical applications.

8200-1310

505XT

LVDC, Extraction/Admission, Standard

A front panel mount next generation user configurable steam turbine extraction/admission digital governor control and protection with advanced integrated multilingual interface HMI screen.

8200-1312

505XT

LVDC, Marine, Extract/Admin, HAZLOC

A front panel mount next generation user configurable steam turbine extraction/admission digital governor control and protection with advanced integrated multilingual interface HMI screen.

8200-1340

Flex500

LVDC, Front Panel, Standard

A robust industrial front panel mount programmable real-time, deterministic controller with integrated HMI display for compressors and turbines in standard locations with low voltage (18-36 Vdc) power input.

8200-1341

Flex500

AC/DC, Front Panel, Standard

A robust industrial front panel mount programmable real-time, deterministic controller with integrated HMI display for compressors and turbines in standard locations with high voltage (88-264 Vac or 90-150 Vdc) power input.

8200-1343

Flex500

LVDC, Front Panel, Standard

A robust industrial front panel mount programmable real-time, deterministic dual redundant controller with integrated HMI display for standard locations with low voltage (18-36 Vdc) power input.

8200-1344

Flex500

AC/DC, Front Panel, Standard

A robust industrial front panel mount programmable real-time, deterministic dual redundant controller with integrated HMI display for standard locations with high voltage (88-264 Vac or 90-150 Vdc) power input.

8200-1345

Flex500

LVDC, Front Panel, Marine, HAZLOC

A robust industrial front panel mount programmable real-time, deterministic, dual redundant controller with integrated HMI display for compressors and turbines in ATEX & Marine applications and hazardous rated locations with low voltage (18-36 Vdc) power input.

8200-1500

Peak200

LVDC, Standard Location

Bulkhead, low voltage DC standard location with integrated full color display for steam turbine digital governor control with overspeed protection.

8200-1353

Flex500

LVDC, Back Panel, Standard

A robust industrial back panel mount programmable real-time, deterministic dual redundant controller for standard locations with low voltage (18-36 Vdc) power input.

8200-1501

Peak200

HVAC, Standard Location

Bulkhead, high voltage DC standard location with integrated full color display for steam turbine digital governor control with overspeed protection.

8200-1502

Peak200

LVDC, Zone 2 ATEX

Bulkhead, low voltage DC Zone 2 ATEX with integrated full color display for steam turbine digital governor control with overspeed protection.

8200-1503

Peak200

LVDC, Standard Location

Panel, low voltage DC standard location with integrated full color display for steam turbine digital governor control with overspeed protection.

8200-1504

Peak200

HVAC, Standard Location

Panel, high voltage DC standard location with integrated full color display for steam turbine digital governor control with overspeed protection.

8200-1300

505D

LVDC, Standard

Configurable steam turbine governor control with integrated multilingual HMI screen for standard locations with low voltage (18-36 Vdc) power input.

MNPLUS-Family

MicroNet Plus

Dual Redundant Control

Woodward’s MicroNet™ Plus customizable control system is a flexible, state-of-the-art system specifically designed for controlling gas and steam turbines. The MicroNet Plus control system provides a flexible platform to control any prime mover and its associated processes.

MNTMR-Family

MicroNet TMR

Triple Redundant Control

MicroNet TMR’s superior architecture and diagnostic coverage combine to create a system with 99.999% availability and reliability. The MicroNet TMR can be applied as a component of protection and safety systems to allow the overall system to meet IEC61508 SIL-3 compliance standards.

8440-2222

easYgen | LS-6XT

CONTROL-LS-612XT-P1

Woodward’s easYgen | LS-6XT control is synchronizer controller with integrated mains decoupling and protection features designed for critical power applications.

8440-2170

SPM-D2-10B-PSY5-FU-D

CONTROL-SPM-D2-10B/PSY5-FU-D

The reliable SPM-D2-10B-PSY5-FU-D digital synchronizer for single/dual phase AC generators equipped with compatible speed controls and automatic voltage regulators.

8440-2297

DTSC-200A

CONTROL-DTSC-200A-352-P1

The DTSC-200A is the ultimate control for ATS (automatic transfer switch) builds.

8440-2299

DSLC-2XT

Digital Synchronizer and Load Control, Redundant Communication, Configurable

DSLC-2XT combines synchronizer, load sensor, load control, dead bus closing system, VAR, power factor, process control and hot swap redundant load share communication, all in one powerful package.

8440-2304

IKD-IN-16

16 channel discrete input module, 12/24VDC

The IKD-IN-16 expands digital inputs to Woodward power management controllers or to your PLC based distributed control system over CAN bus.

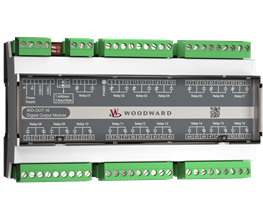

8440-2305

IKD-OUT-16

16 relay output module, 24VDC

The IKD-OUT-16 expands relay outputs to Woodward power management controllers or to your PLC based distributed control system over CAN bus.

8440-1877

MSLC-2-5

CONTROL-MSLC-2-5

The MSLC-2 control combines synchronization, dead bus closing, utility/intertie load sensor, baseload control, import/export control, VAR, power factor, and a master process control in one powerful package.

8440-1878

DSLC-2-5

CONTROL-DSLC-2-5

The Woodward DSLC-2™ (Digital Synchronizer and Load Control) is a microprocessor-based synchronizer and load control designed for use on three-phase AC generators.

8440-2082

easYgen-3200XT

CONTROL-EASYGEN-3200XT-P1

The easYgen-3200XT combines complete engine-generator control and protection with advanced, peer-to-peer paralleling functionality and innovative features in a robust, attractive and user-friendly package.

8440-2085

easYgen-3500XT

CONTROL-EASYGEN-3500XT-P1

The easYgen-3500XT combines complete engine-generator control and protection with advanced, peer-to-peer paralleling functionality and innovative features in a robust, attractive and user-friendly package.

8440-2087

easYgen-3400XT

CONTROL-EASYGEN-3400XT-P2

The easYgen-3400XT combines complete engine-generator control and protection with advanced, peer-to-peer paralleling functionality and innovative features in a robust, attractive and user-friendly package.

Our Industries

With over 50 years of heritage in the aerospace industry, Woodward applies total system solutions to your needs. We are at the forefront of the industry in developing and delivering motion control and integrated propulsion systems.

Read moreAEROSPACE

Understanding that system reliability is a major requirement for oil and gas, petrochemical, and process plant industries, Woodward’s control, actuation, valves, and protection systems are designed to meet the high level of reliability and redundancy required across challenging industrial applications.

Read moreINDUSTRIAL

With over 50 years of heritage in the aerospace industry, Woodward is a major controls supplier for fixed- and rotor-wing aircraft and a turbine engine controls and combustion supplier across the military aerospace segment.

Read moreMILITARY

Through the ability to provide control over both the generator and the prime mover, our controls and systems help power generators deliver consistently reliable power and coordinate a variety of distributed resources. Backed by decades of experience with generator controls, load sharing, synchronization, and power protection technologies, Woodward's power generation control solutions set standards worldwide.

Read morePOWER

Woodward components and engine control systems are used in diverse mobile and industrial equipment such as forklifts, excavators, trains, trucks, buses, or stationary engines. We understand that your key concerns are emissions, productivity, and lower operating cost.

Read moreTRANSPORTATION

AEROSPACE

INDUSTRIAL

MILITARY

POWER

TRANSPORTATION

Woodward’s purpose is to design and deliver energy control solutions our partners count on to power a clean future.

17

Countries

9,000

Members

$2.9

Billion in Sales (2023)

NOTEWORTHY

Industrial

Understanding that system reliability is a major requirement for oil and gas, petrochemical, and process plant industries, Woodward’s control, actuation, valves, and protection systems are designed to meet the high level of reliability and redundancy required across challenging industrial applications.